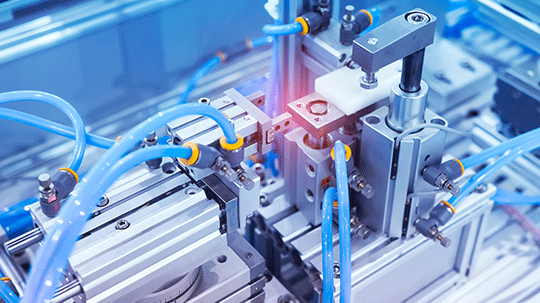

Compressed Air Systems

Benefits of Compressed Air Systems

Compressed air systems can account for 10 percent or more of a facility’s electricity use. Improperly maintained compressed air systems can cost your business reliable, quality air and significantly impact your operating expenses.

On the supply side (where air is compressed), it’s important to use the right combination of compressors, air receivers, and air dryers. On the demand side (where air is used), there are quick fixes such as leak remediation, air-entraining nozzles, and control adjustments to improve system reliability.

Benefits of running energy-efficient compressed air systems include:

- Profitability — running your compressed air system efficiently can lead to long-term reduced energy costs

- Reliability — with easy, quick fixes, your system can run more reliably, reducing maintenance needs and costs

- Comfort — an efficiently run compressed air system allows for quality air and comfort in your facility